Plate Coating Services

Together, we create greatness

Producing high-quality ELISA kits starts with expertly coated microtiter plates. Antibodies and proteins are bound to the plastic surface to ensure optimal assay performance and consistency.

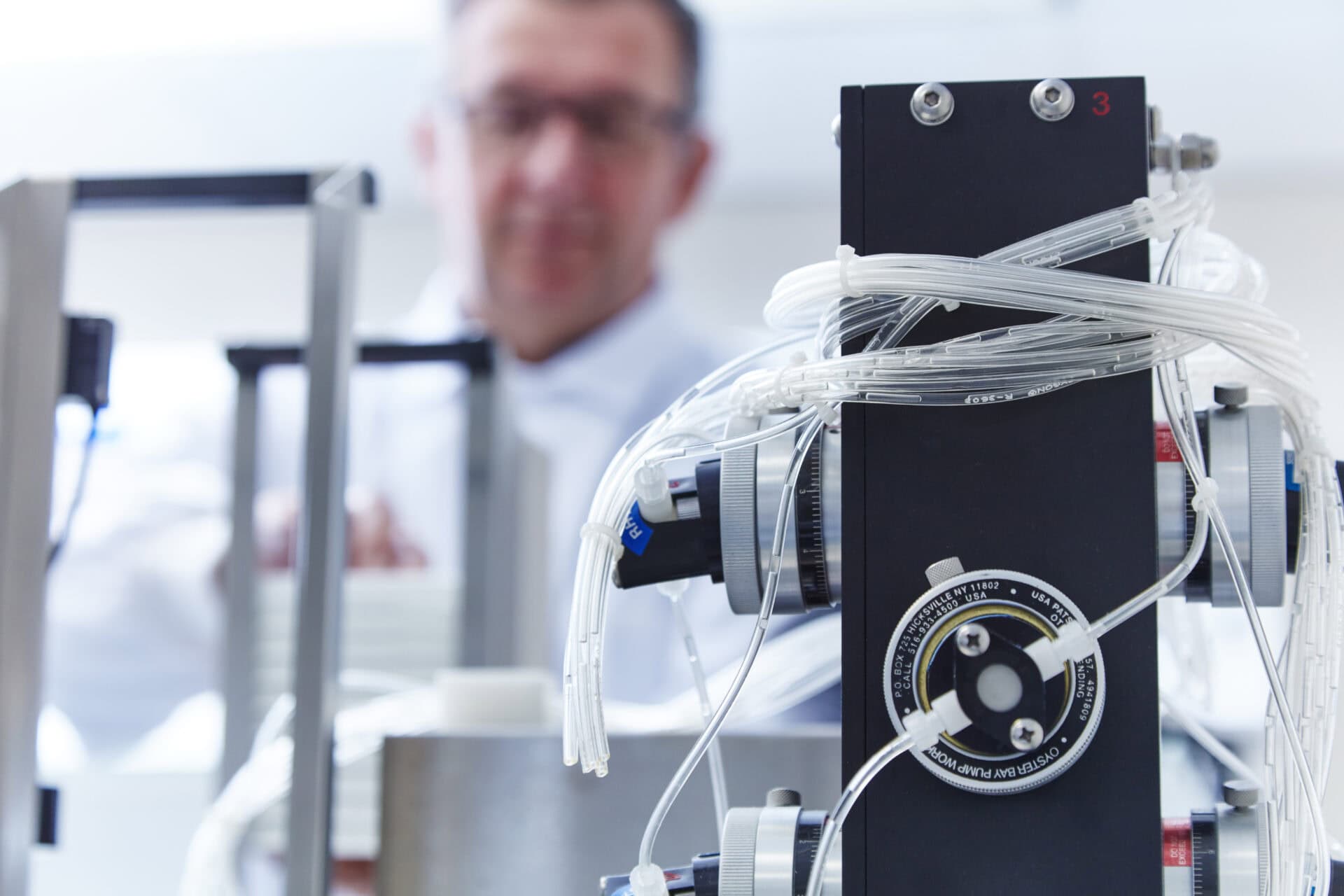

At Biocult, we rely on the advanced robotic system from Oyster Bay Pump Works (OBPW) for the coating, blocking, and conserving of 96-well plate batches. This robotic system automates the entire process, from precise filling with coating solution to efficient blocking and conserving, ensuring accuracy and reproducibility. The robotic system also supports additional applications such as plate washing and fluid handling, offering complete flexibility for microtiter plate processing.

Looking to scale up production or need expert support for your coated microtiter plate workflow? Choose Biocult and make your work easier. We’re here to help when your company faces capacity limits or expertise shortages. At Biocult, we combine personal commitment with deep technical know-how to deliver tailor-made, high-quality results. Our practical, solution-driven approach ensures efficiency and excellence from start to finish. With open communication, trusted collaboration, and full EN ISO 13485:2016 compliance, Biocult is your partner for reliable contract manufacturing and contract research empowering your success, every step of the way.

Reliable Microtiter Plate Automation

Biocult’s advanced OBPW robotic system automates coating, blocking, and glazing of 96-well microtiter plates for consistent ELISA performance.

Curious what we can do for you? Contact us and let’s create greatness together!

Start a Project

Let’s make something great together. Feel free to contact us for more information via the contact form.